WEAVING the grass

OUR TECHNOLOGY

\ ADVANTAGE OF INNOVATION

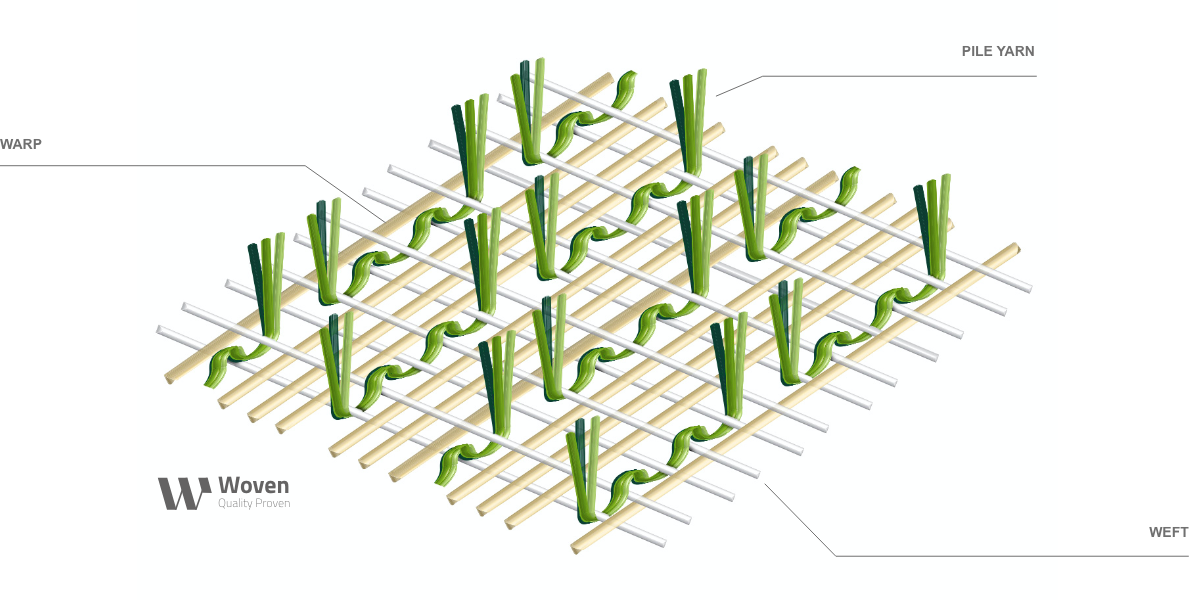

Why Weaving?

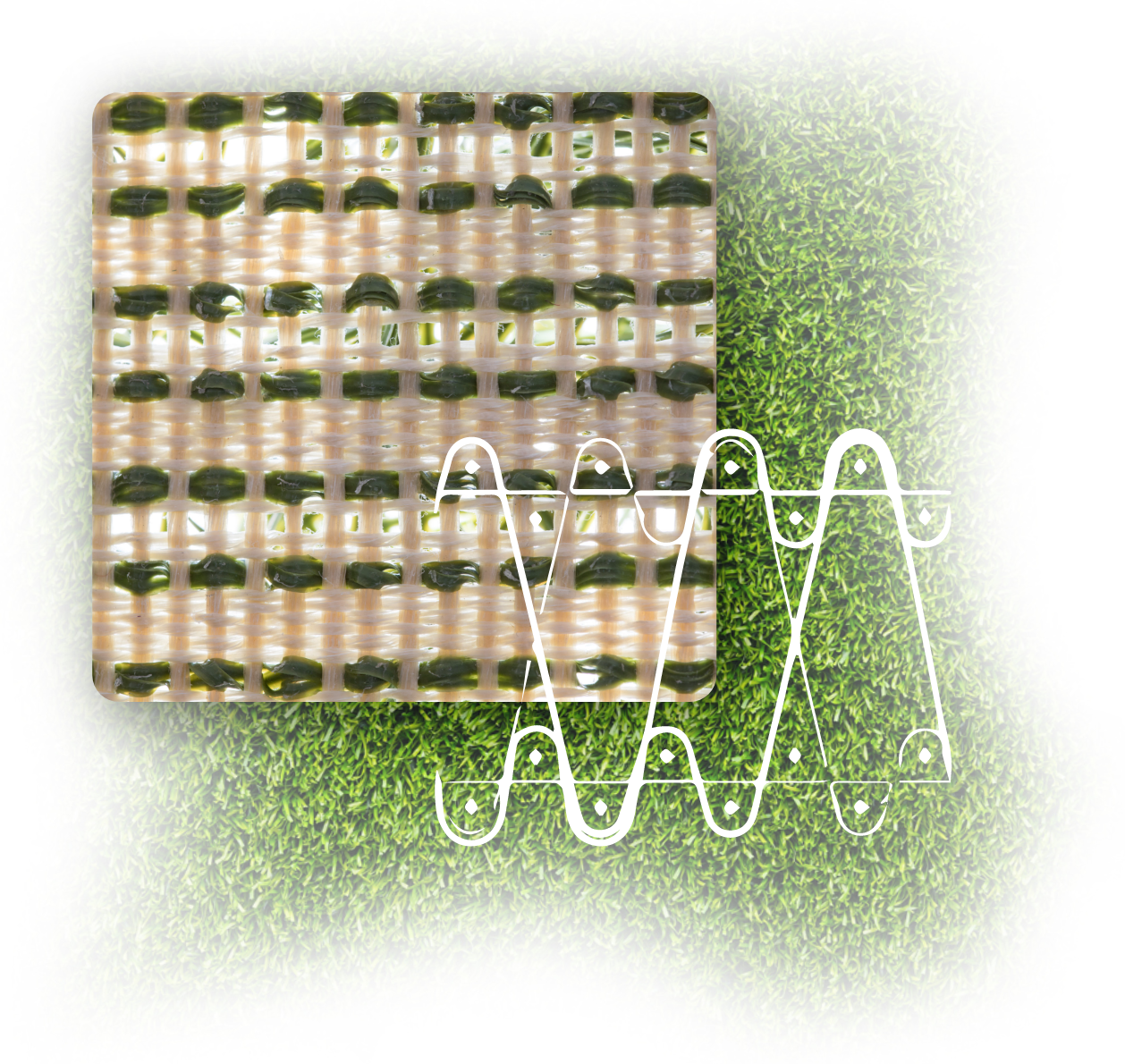

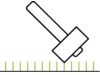

WEAVING and TUFTING technologies are two different methods of producing artificial turf. Weaving is a method of simultaneously braiding warp, weft and pile fibres into a single product, on the same loom, at the same time. Astonishing bundle attachment strength is achieved by weaving W-type yarn. The most common tufting method is a process of needling the fibres into the ready primary backing that needs to be fixed with a thck secondary backing layer of latex or PU.

\ WHY WOVEN GRASS?

EXTREMELY DURABLE SURFACE : strong pile fixation increases the life of the turf. The highest quality is proven and guaranteed by innovative weaving technology.

EFFICIENCY OF INSTALLATION AND MAINTENANCE : specially designed pile distribution and vertical arrangement of the blades make the installation and maintenance easier. After filling up the grass, 100% of fibres stay above the infill.

100% RECYCLING : all our products are 100% recyclable.

PERFECT SURFACE 365 : surface recommended for use throughout the year. The structure of woven fabrics ensures unique water permeability. The woven surface remains extremely even, including in winter.

ECO-LOGIC : we use environment friendly backing glue. The application rate is reduced by 90%. No-SBR infill systems are also available.

NATURAL LOOK : weaving technology enables the use of three shades of green, so that the turf is similar in appearance to natural grass.

EXTREME WATER PERMEABILITY : unbeatable by tufted turf, a minimum of 4.700 mm/h

WOVEN-IN LINING OR LOGO : the unique possibility to have your own logo or special lining woven on the field

\ DYWILAN WOVENGRASS TECHNOLOGY

\ Projects

Our wovengrass projects

We work with: